Wearlon® Industrial Coatings are durable, non-stick, anti-friction coatings with a waterborne chemistry, providing easy clean, hydrophobic properties to a huge range of industries.

The Wearlon coating system can be applied to virtually any substrate, and provides hydrophobic, non-stick and friction reducing properties.

What makes Wearlon® different?

-

Unlike PTFE/Teflon-type non stick coatings that require high heat assistance for curing, Wearlon is room temperature cure industrial non-stick coating. No heat is required. Now, a tough non stick can be applied any time, anywhere.

-

Wearlon is a water based, low VOC, environmentally friendly, silicone-epoxy coating.

-

Wearlon is a technologically advanced silicone-epoxy in that it exists as a BLOCK COPOLYMER. That means the silicone molecules are actually bonded to the epoxy molecules fully cured and grafted throughout the matrix of the coating. That means no leaching or migrating silicone. That means no blooming free silicone. That means combining superior, non-stick, lubricity to tough industrial protection.

-

Wearlon coatings are extremely simple and easy to apply using standard methods such as spraying, brushing, or rolling.

-

The coating, and its non-stick repellent properties are tough, durable, and abrasion resistant.

-

Highly rated for corrosion resistance and protection in all environments.

-

Comes in any color, matte or gloss.

-

No primer required in most cases. A single topcoat application and you’re done!

-

Adheres tenaciously to just about anything and everything – wood, metal, concrete, plastic, etc.

-

It is less costly, lasts longer, and out-performs other coatings.

To learn more or place an order, visit WearlonCorp.com for Data Sheets, Test Data and MSDS.

For over 20 years, Wearlon performance coatings have set the standard for non-stick, graffiti resistant, easy cleaning, long lasting, industrial coating systems for a wide range of applications.

Wearlon coatings have been proven to:

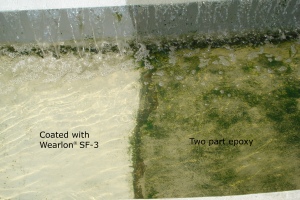

Resist fouling in salt and freshwater environments.

Wearlon is being used on penstocks, intake trash racks, and secondary clarifiers in waste water treatment facilities. Specifically, Wearlon SF-3M has been proven to be a long lasting and reliable coating system for the control of zebra mussels and other fouling organisms.

Wearlon SF-3M is the perfect spray on hydrophobic coating for resisting algae, protecting concrete, and making concrete surfaces easy to clean – even when submerged in water.

SF-3M is also extremely corrosion resistant, even in the most extreme environments. When applied directly to cold rolled steel, Wearlon can seal the surface of flash-rusted steel, preventing further oxidation. It is currently being used on steel in tough, salt & spray heavy coastal areas with great results.

Reduce Drag.

Drag Reduction + Fouling Resistance = Less Fuel consumption and Higher Top Speeds.

Wearlon coatings like Speedcoat-49 present hydrophobic properties and an extremely low surface energy which allows any water vessel to move more efficiently through the water.

As an environmentally safe alternative to toxic copper and tin-laden ablative coatings, Wearlon has become the leader in speed coatings for boats in both freshwater and marine markets. Wearlon Speedcoat-49 is used by multiple national champions and world record holders in hydroplane racing.

Dry film Lubrication.

Wearlon coatings have an extremely low coeffecient of friction, allowing for materials to slide over one another easily with little heat buildup, material aggregation or clogging.

Applying Wearlon SF-4 to truck beds, manufacturing chutes and steel construction equipment greatly reduces cleanup, down time and load residue, which helps lower overall labor cost.

Non-Stick. Wearlon has patented technology that puts the non stick, easy to clean attributes of a PTFE coating into a waterborne system, making it safe and very easy to apply. There is no need to apply heat to Wearlon to “bake” it on. There are no toxic solvents, meaning application in sensitive areas like grain silos, oil platforms and manufacturing facilities, becomes as easy as rolling it on and walking away. For example, one application of Wearlon Wetlander on the interior of their silo gave a Portland cement distributor a slick, non-stick surface that allows the cement to slide down the side of the silo without sticking or clumping. This allows for faster loading and unloading, while limiting downtime.

Potato and sugar beet processors in the Midwest USA are using Wearlon 2020.98 on their harvesting bins and conveyance systems to prevent ice and mud from clogging up the movement of field potatoes into their highly specialized process and time sensitive process.

Wearlon is used in the Pulp and Paper industry as a release coating on the forming fabrics of industrial paper manufacturing facilities all over the world. By coating the wire web, doctor blades and rollers, the stickiness of the lignin is mitigated and the paper-making process runs smoothly.

Anti-Graffiti. Our anti-graffiti formula, Wearlon 711, is being applied to concrete, steel, aluminum, brick, wallboard and even signage to protect from all paints, inks, and permanent markers. Wearlon 711 can be applied as a clear coat indoors or out, without fear of UV degradation. Quite simply, Wearlon 711 is the most effective and user friendly anti-graffiti product on the market. Used by townships, municipalities, private corporations and governments all over the world.

Easy Clean. Fortune 500 automobile manufacturers use Wearlon 4545.76 to protect the armature of their painting robots from overspray. If the overspray was allowed to stay on the spray arms, the weight and balance of the armature would be affected, causing inconsistencies and delay. Before Wearlon, these robotic arms would have to be shut down periodically for intensive breakdown and clean-up. Now, after an application of 4545.76, to the spray-bots clean-up with a simple wipe down with very little down time.

Wearlon 4545.76 is also utilized as an adhesive release agent for the production of auto interiors. Previously, Teflon-based coatings were used during the thermoplastic forming of molded plastic parts. The Teflon coating did not fully release, and had adhesion issues. By coating aluminum forming molds with 4545.76, the powerful reactive polyolefin adhesives are easily release from the coated substrate, outperforming Teflon and other tested coatings.

Form/Mold Release. Utilized in the production of aircraft, Wearlon 2020.98H has been a workhorse in the industry for years. By coating the aluminum stretch-forming armature with 2020.98H, process engineers have enjoyed a permanent release coating that does not leave an oily residue on their newly formed parts, saving time and money. Below is an example of a Wearlon coated tool that reduces friction and acts as a permanent dry-film lubricant, releasing stretch-formed aluminum components for hundreds of cycles with no downtime.

Thanks for sharing useful information

Hello my name is Sarah Herbold and I am from Ceno Technologies contacting you in regards to possibly working together to combine our specialty cenosphere coatings to create something new and innovative. Our silver coated cenospheres can supply electrical conduction and infra-red (IR) reflection AND simultaneously perform like a ceramic in thermal insulation, low cost, low maintenance and ease of use. Silver Coated Cenospheres from Ceno Technologies are extremely reflective, lightweight and can exhibit an EMI shielding effectiveness of 60dB from 100 MHz to 25 GHz and higher. If this sounds like something you would be interested in please contact me back at sherbold@cenotechnologies.com and visit our website to see our other specialties that might work for other ideas!

Thanks and I look forward to hearing from you,

Sarah Herbold